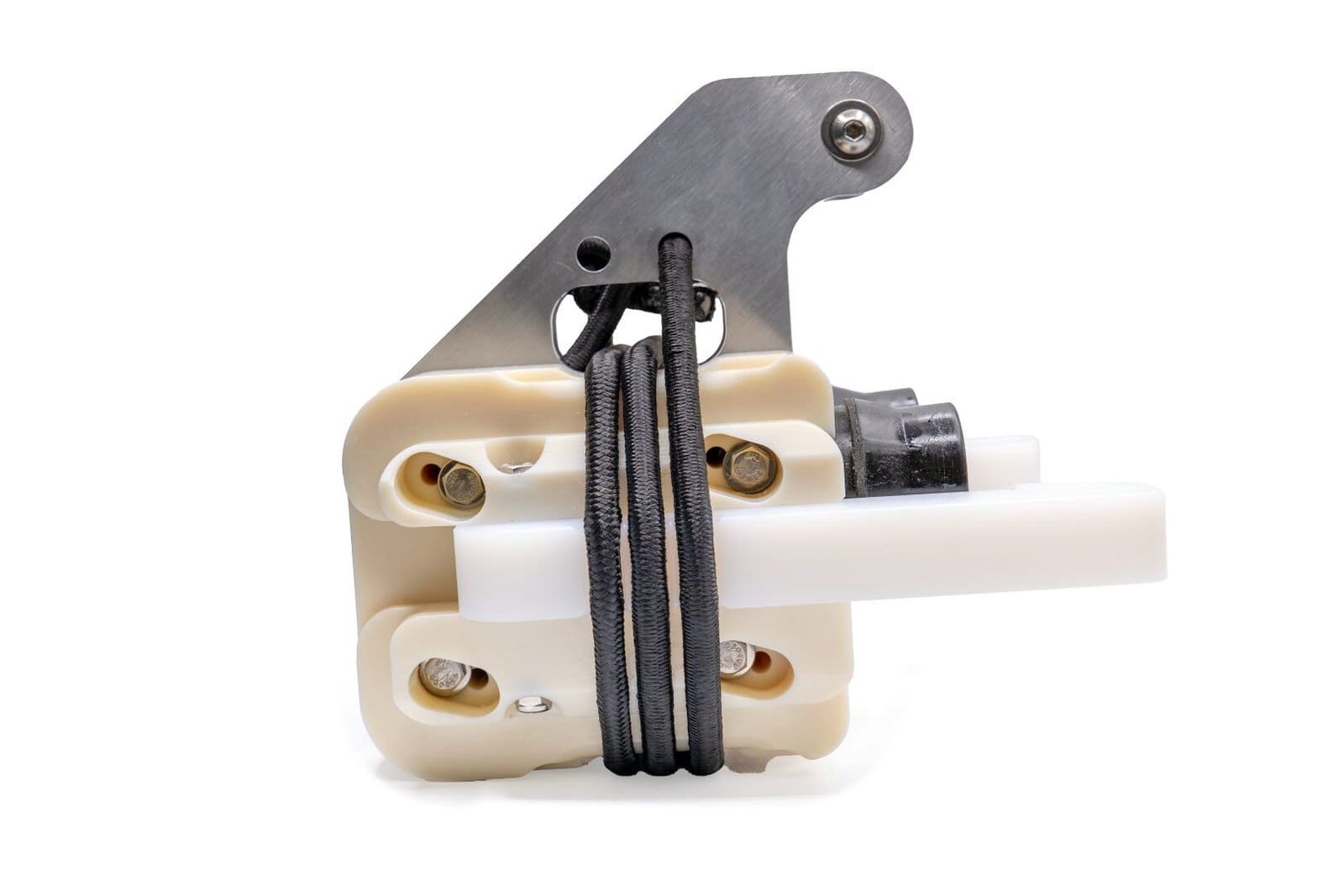

The skyTECH Catch Block is CNC machined from solid nylon and features a robust design with self-lubricating inserts machined to the site’s cable diameter and can be replaced as they wear out. This ensures the cable in your braking zone does not contact any metal components, extending the lifetime of the cable in this high-traffic area.

The special rubber-blend impact bumpers absorb and disperse the energy upon braking while the machined UHMW teeth latch onto the Rocket trolley’s endplate. The catch block can be used in a simple 1:1 braking system, 2:1 pulley reduction, or nearly any other braking setup.

Aluminum plates are mounted within the Catch Block to serve as mounting points, extending the lifetime of the Catch Block.